HDI PCB Technology

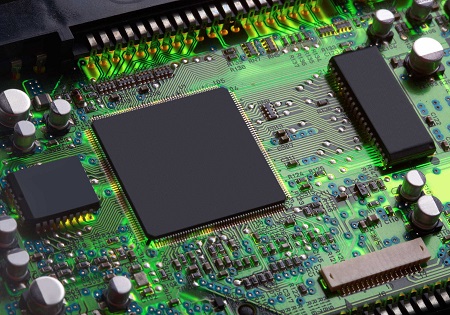

Over the past couple of decades we have seen consumer and other electronics devices reducing in weight and size while improving phenomenally in speed, performance and power consumption. High Density Interconnect PCB or HDI PCB Layout is one of the leading reasons for this transformation. HDI PCB Layout has high-density attributes like laser microvias, fine lines and high-performance thin materials. HDI PCB Layout Designs have a higher wiring density per unit area than conventional PCBs and are ideal for complex small form factor designs. High Density Interconnect PCB enable more space on a printed circuit board, while making them more efficient and allowing faster transmission.

What is High Density Interconnect PCB?

HDI PCB Layout offers numerous advantages, starting with more interconnections in smaller areas resulting in miniaturization of printed circuit boards. High Density Interconnect PCB contains microvias of .006 or less in diameter. The increased density in HDI PCB enables PCB designers to incorporate more functions per unit area. HDI PCB Layout inherently provide better signal integrity as compared to regular PCBs given reduction in stray capacitances and inductances due to small blind and buried vias. The advancement towards High Density Interconnect PCB Technology in PCB layout and analysis is being driven by new High Density Interconnect PCB methodologies, miniaturization of components and semiconductor packages which support a variety of advanced features that are getting utilized in revolutionary new products in applications such as wearable electronics, touch screen computing, compact, small footprint gadgets, defense and aerospace.

HDI PCB Layout offers numerous advantages, starting with more interconnections in smaller areas resulting in miniaturization of printed circuit boards. High Density Interconnect PCB contains microvias of .006 or less in diameter. The increased density in HDI PCB enables PCB designers to incorporate more functions per unit area. HDI PCB Layout inherently provide better signal integrity as compared to regular PCBs given reduction in stray capacitances and inductances due to small blind and buried vias. The advancement towards High Density Interconnect PCB Technology in PCB layout and analysis is being driven by new High Density Interconnect PCB methodologies, miniaturization of components and semiconductor packages which support a variety of advanced features that are getting utilized in revolutionary new products in applications such as wearable electronics, touch screen computing, compact, small footprint gadgets, defense and aerospace.

HDI PCB Layout Designs

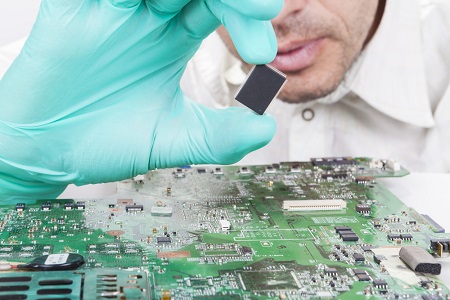

At Mistral, we design cost-effective High Density Interconnect PCB Layout Designs using different types of vias/microvias techniques like stacked and staggered vias/microvias, blind and buried vias, fine lines and spaces, sequential lamination and via-in-pad technology. One of the main advantages of HDI PCB Layout is that they not only use Vias to create connections between layers, but also use Laser Drilled Microvias, which are smaller and more effective in terms of space. Although the microvia process increases the cost of the High Density Interconnect PCB, with proper design and reduction in layer count, we can reduce the cost for material square inches and layer count significantly.

Mistral’s team has extensive experience in designing cost-effective HDI PCB layout designs including microvias, blind and buried vias, fine lines and spaces, sequential lamination, via-in-pad techniques that help reduce size and weight, as well as enhance electrical performance of embedded devices. Our HDI PCB Layout Services includes Library management, PCB Layout and Analysis, Power Integrity Analysis Services, Signal Integrity Analysis Services, Structural Analysis Services and Thermal analysis Services.

High Density Interconnect PCB Manufacturing

A High Density Interconnect PCB design and manufacturing requires an advanced level of technical expertise. Our eco-system of PCB and High Density Interconnect PCB manufacturing companies and collaboration with Avalon Technologies, a global ESM company, enables us to provide our customers with a seamless product and system design experience. Our expertise in High Density Interconnect PCB includes handling the power integrity impact while designing using HDI PCB Technology.

A High Density Interconnect PCB design and manufacturing requires an advanced level of technical expertise. Our eco-system of PCB and High Density Interconnect PCB manufacturing companies and collaboration with Avalon Technologies, a global ESM company, enables us to provide our customers with a seamless product and system design experience. Our expertise in High Density Interconnect PCB includes handling the power integrity impact while designing using HDI PCB Technology.

This includes the effects of the mounted inductance of decoupling capacitors, changes in plane performance due to reduction in perforation from chip pin-outs, and the inherent plane-capacitance changes from using dielectrics of various thicknesses. Know more about our HDI PCB Layout and Design Expertise. Click here to read a blog on Brief on High Density Interconnect – HDI PCB Technology

EXPERTISE

HDI PCB Technology

- Selection of HDI PCB layout techniques based on Size, Performance and Components

- Innovative design methods in Fine Pitch Micro BGA designs

- Stacked and staggered vias/microvias, blind and buried vias, fine lines and spaces,

sequential lamination and via-in-pad technology

- Up to 0.37mm BGA pitch designs with 2 mil/2mil track/spacings

- High Density Interconnect PCB Layout Designs with stacked and staggered micro-vias

- Board/System level Signal Integrity, EMI/EMC & Thermal Analysis

- Signal performance analysis in HDI PCB for Reflections, Timing, BER, EYE opening

- DC drop analysis in power supply rails

- Handling power integrity impact while designing using

High Density Interconnect PCB techniques

HDI PCB Technology

- Selection of HDI PCB layout techniques based on Size, Performance and Components

- Innovative design methods in Fine Pitch Micro BGA designs

- Stacked and staggered vias/microvias, blind and buried vias, fine lines and spaces,

sequential lamination and via-in-pad technology - Up to 0.37mm BGA pitch designs with 2 mil/2mil track/spacings

- High Density Interconnect PCB Layout Designs with stacked and staggered micro-vias

- Board/System level Signal Integrity, EMI/EMC & Thermal Analysis

- Signal performance analysis in HDI PCB for Reflections, Timing, BER, EYE opening

- DC drop analysis in power supply rails

- Handling power integrity impact while designing using

High Density Interconnect PCB techniques