Design and Development of High-Definition, Rugged Digital Video Recorder

Introduction

Digital Video recorders are employed in several demanding defense and homeland security applications like Airborne Video recorder systems, Real time Data acquisition systems, Telemetry systems and Video surveillance systems & security solutions. They are expected to be rugged, small, lightweight systems capable of multi-channel HD video recording with playback.

This case study showcases Mistral’s expertise in designing a flexible and easily upgradeable Video recording & processing solution with high resolution and frame rate for defense and aerospace applications.

The Customer

The customer is a privately held company with business activities in the telecommunications, defense and contract manufacturing domains. These include sales and support of wireless communication, radar and communication systems, design and manufacture of identification friend or foe (IFF) systems, microwave tactical data links and flight management systems for unmanned aircraft systems (UAS).

The Requirement

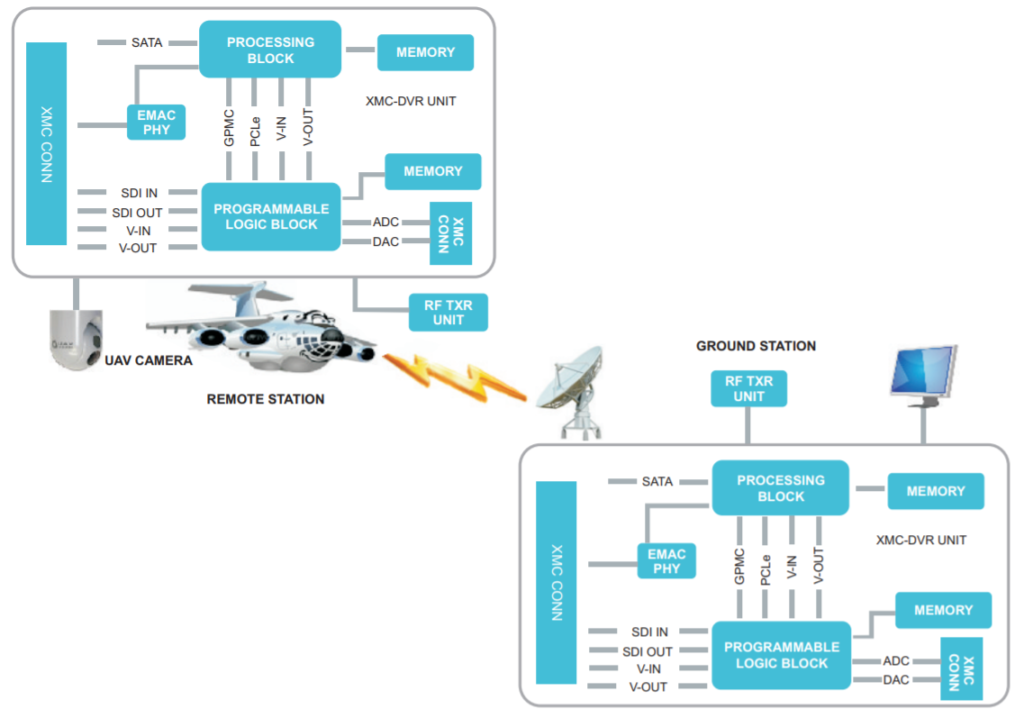

The customer approached Mistral to design and develop a Digital Video Recorder (DVR) solution for airborne applications. The unit would have to prove reliable and long term (8- 10 hrs) functionality under the most severe conditions. For the current application, the Digital Video Recorder units had to be fitted at three locations – Remote Station, Ground Station and Viewing Station.

The solution provided had to meet the following requirements:

- A small form factor, High definition Video processing Engine supporting HD-SDI, HD and SDI formats

- Conduction based Cooling system to protect against external and internal heat generated

- MIL-STD-810F qualification for temperature & vibrations

- MIL-STD-461D/MIL-STD-462D for EMC

The DVR unit mounted on the UAV (remote station) was expected to capture and encode multiple UAV cameras inputs (HD-SDI, HDI, SDI). The encoded data had to be converted to Analog signals before being transmitted to the ground station. The DVR unit in the ground station had to decode the received signal to display for immediate viewing. The same data had to be also sent via Ethernet to the Viewing station where the captured data would be studied in detail and stored for future reference. The DVR had to perform Encode, Decode and Transcode operations for the following video compression formats: H.264, MPEG2, MPEG4 SP/ASP in 1080p video resolution.

Solution Provided

To meet the customer’s small form factor requirement for the DVR, Mistral provided an XMC based video processing unit based on TI’s DM8168 Video processor & Arria II FPGA from Altera. The compression/decompression and encoding is performed by the processor and the FPGA is the transceiver. The FPGA video input on the Remote station DVR unit receives raw video from the UAV camera & transmits it to the processor. The Processor encodes the video along with other flight data parameters and packetizes the data for transmission. The FPGA interfaces with the host processor through PCIe and receives the packetized data which is sent to the RF link over DAC interface

The FPGA in the Ground station DVR unit receives the RF signal which is demodulated and retrieved using ADC. For decoding, the data is packetized and sent to the processor over the PCIe link where the video, audio & flight parameters is separated from the packet. The Video bit stream is further processed for storing using SATA interface & for displaying using HD-SDI out interface.

The team at Mistral worked on the design, development and verification of Hardware and firmware, system analysis for thermal & mechanical constraints, integration and validation of TI media framework and pre-qualification tests for MIL STD compliance.

To know more about the key features of the system, read full case study.