Advanced X-band Surveillance RADAR for Autonomous Underwater Vehicles

Underwater vehicles, particularly Unmanned Underwater Vehicles(UUVs) and Autonomous Underwater Vehicles (AUVs), play a vital role in safeguarding high-value naval assets like aircraft carriers, submarines, and frigates by patrolling and surveying sea routes. These vehicles significantly enhance sea surveillance by detecting and tracking potential threats, including enemy ships, frigates, boats, underwater drones, submarines, and mines, which may evade traditional surface-based monitoring systems. They enable large naval vessels to detect nearby threats that are beyond the reach of ship radar systems. Equipped with advanced sensors, sonar technology, and increasingly AI-based navigation, UUVs and AUVs extend the detection capabilities of mother ships into contested or challenging waters, all while minimizing risk to crewed vessels and high-value assets.

High-Endurance Autonomous Underwater Vehicles (AUVs) can operate independently for up to 15 days, undertaking a range of ISR (Intelligence, Surveillance, and Reconnaissance) missions with minimal human intervention.

This case study showcases Mistral’s expertise in designing and developing an advanced, portable X-band surveillance radar specifically tailored for AUVs engaged in ISR operations. The radar system provides real-time detection and tracking of surface threats, significantly enhancing situational awareness and strengthening naval defense capabilities.

The Customer

The client is a prominent defense laboratory that specializes in developing complex radar systems for ground, shipborne, and airborne platforms, and required a radarsolution optimized for underwater vehicle deployment.

The Requirement

The project requirements specified a compact, high-performance portable X-band radar transceiver for the HEAUV, with the capability to perform real-time detection and tracking of sea surface targets. Key specifications included:

- X-band operation

- Transmit-Receive modules contained in high-pressure rate Radome

- Operational capabilities: 360 azimuth coverage and sub-surface resilience to depths up to 300 meters

- Detection range of minimum 300 m and max 5 km for 5 m² RCS targets

- Physical constraints: Φ300mm x 300mm (height) & weighing under 30 kg

- Environment durability: Withstanding pressures up to 45 bars with operational compliance to MIL-STD-461G and JSS55555 standards

Scope of work: The project encompasses the design, development, and deployment of an Advanced Portable X-band Surveillance Radar tailored for a HEAUV. The scope includes comprehensive System Engineering to define specifications and ensure interoperability, hardware design and development, and software development to integrate radar functionalities with autonomous control systems, system integration, and testing to confirm performance standards, delivering a fully functional surveillance radar system optimized for extended underwater operations.

Solution Provided

Mistral developed a custom-built radar transceiver system that met the client’s stringent requirements while integrating advanced design features for optimal performance in underwater ISR operations. Key aspects of the solution

Mistral developed a custom-built radar transceiver system that met the client’s stringent requirements while integrating advanced design features for optimal performance in underwater ISR operations. Key aspects of the solution

included:

X-Band Cylindrical Slotted Waveguide Antenna Array: The radar utilizes a cylindrical slotted waveguide antenna array (Linear array with 4 slots) that provides 360 coverage with a scan rate of 7.5 RPM, offering continuous situational awareness and reliable tracking. This antenna configuration with 32 antenna sticks ensures effective surface and near surface detection, even when submerged, covering a minimum range of 300 meters and a maximum detection range of 5 km for targets with a radar cross section (RCS) of 5 m².

High-Pressure Rated Radome: To operate reliably at depths up to 450 meters, the radar is encased in a high-pressure-rated radome, able to withstand pressures up to 45 bar. The radome, engineered for X-band, is constructed from Quartz Fibre and meets IP68 standards. Coated with a low-loss, hydrophobic layer, the radome repels moisture, enhancing signal clarity in underwater environments. Additionally, the coating provides anti-fouling and anti-corrosive protection, ensuring durability during immersion in saline water.

Transmit/Receive Modules: Mistral designed and developed the Tx/Rx Front-End Card – an X-band Transmit/Receive Module (TRM) – incorporating a high-power amplifier, low-noise amplifier (LNA), bandpass filter, and SPDT switch. Both conduction-cooled cards are equipped with blind-mate connectors, ensuring easy integration and reliable performance.

Compact Exciter and Quad-Channel Receiver Modules: Mistral designed and integrated a lightweight, compact exciter and two quad-channel receiver modules to deliver high sensitivity and clarity in radar data capture, enhancing signal processing for optimal target detection across various ranges. The exciter/receiver subsystem enables the switching of eight receiving channels across four antenna sectors within the transceiver unit, along with transmit signal (TXD) generation. It performs single down conversion of the received signal, followed by analog-to-digital conversion of eight intermediate frequency (IF) signals and digital down-conversion of all data. Additional functionalities include I/Q data multiplexing, burst data appending, time-stamping, and Ethernet data transmission, as well as waveform generation, local oscillator (LO) and clock generation, and DC-DC power conversion.

Low Power Signal and Data Processor Engine: The Radar system is powered by a low-power signal and data processor engine built around Intel Agilex FPGA. This processing engine enables real-time data acquisition,analysis, and target tracking with minimal power draw, a critical feature for prolonged autonomous operations on the HEAUV. Designed to meet the MIL-STD-461G and JSS55555 standards, the system is robust across a temperature range of -10 C to +55 C, making it suitable for diverse maritime climates.

Mechanical Monoblock Chassis and PT45 Water-Blocked Cabling: The radar and all electronics are housed within a conduction-cooled monoblock chassis, ensuring efficient thermal management under continuous operation. A PT45 water-blocked cable assembly is used to provide reliable, waterproof external interfaces, supporting robust connectivity and operational integrity under high-pressure conditions.

Technical Specifications

- Operating Band: X-band

- Antenna Type: Cylindrical slotted waveguide antenna array

- Azimuth Coverage: 3600 coverage

- Scan Rate: 7.5 RPM

- Range:

-Minimum: 300 m

-Maximum detection: 5 km for 5 m² RCS targets

-Instrumented Range: 10 km

-Range Resolution: 7.5 m - Dimensions: Diameter 300 mm, height 300 mm

- Weight: 22 kg

- Power: 140W at 28V DC

- Environmental Durability: High-pressure radome rated at 45 bar; conduction-cooled mono-block chassis

- Signal Processing: Intel Agilex FPGA-based low-power engine

- Compliance: MIL-STD-461G, JSS55555

- Operating Temperature: -100 C to +550 C.

Hardware Development

Mistral was responsible for designing and developing all the hardware modules and mechanical components for the Portable X-band Radar. Mistral undertook the design, development, fabrication, and subsystem testing of these hardware modules and mechanical structures, performing necessary analyses to ensure the successful realization of the Portable Transceiver Unit.

Software/Firmware Development

Mistral developed all firmware and software for the system, in addition to implementing the test cases provided by the customer to meet functional and

real-time performance requirements.

The functionalities of the Waveform Generator and Signal Processor were implemented in VHDL. Key functions include Digital-Down Conversion, Digital Beam Forming, Digital Pulse Compression, Moving Target Indication, Coherent/Non-Coherent Integration, CFAR, BMWD, and Scan-to-Scan Discrimination. Algorithms and baseline code for these modules were provided by the customer and were successfully ported onto the system.

Mistral handled the configuration of the RFDAC, timing control, and waveform generation using the JESD protocol. This included setting up an 8-channel ADC for 100Msps data capture, developing firmware to enable data transfer between the SoC-HPS and SoC-FPGA, and designing both 1G and 10G interfaces for external data transfer-from the SoC-FPGA and SoC-HPS to the Data Processor, respectively. The waveform generation card was equipped with an AMD MicroBlaze soft processor, facilitating the reception and transmission of command/control signals from the Agilex board. Mistral has also done the bring-up and testing of all peripherals on the SoC-HPS running Linux 6.1, configuring and verifying each peripheral’s functionality as integrated with the SoC system.

System Assembly and Integration

The System Integration phase involved meticulously assembling all hardware modules and mechanical components of the Portable Transceiver Unit.

Mistral ensured precise alignment and secure housing for each module, followed by integrating the firmware and software components to achieve seamless interoperability. Rigorous checks were conducted to confirm that each subsystem met performance standards and functioned cohesively within the unit. The fully assembled system underwent thorough testing to validate operational readiness, ensuring it met the specified requirements for performance, durability, and environmental resilience.

Testing and Evaluation

Mistral conducted a comprehensive series of tests to ensure the system meets all functional and performance requirements under various operational and environmental condition. The testing process included Functional Tests (FT), Environmental Stress Screening (ESS) and Qualification Tests (QT) as per the MIL-STD-461G, JSS55555 standards.

Challenges

The development of the portable X-band surveillance radar presented several key challenges, particularly in mechanical construction and the integration of

electronics.

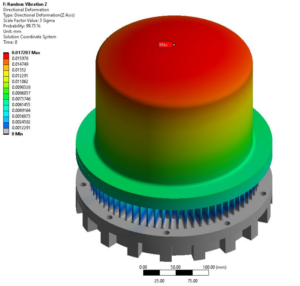

High Pressure Resilience in Mechanical Design

Challenge: Operating at depths of up to 450 meters meant that the radar’s radome and housing needed to withstand pressures up to 45 bars. Ensuring that all components could endure this high-pressure environment without compromising radar performance was a primary concern.

Solution: A custom-designed, high-pressure-rated radome (constructed using Quartz fibre) coated with a hydrophobic layer was developed to withstand

extreme underwater pressures. This required precise material selection, structural testing, and layering to prevent deformation or moisture intrusion, which could affect the radar’s performance.

Compact Mechanical Integration with Thermal Management

Challenge: Integrating the radar components within the constrained size of Φ300mm x 300mm required highly compact placement of all electronics. Given the limited internal space, ensuring proper thermal management to avoid overheating was challenging.

Solution: Mistral employed a conduction-cooled mono-block chassis that served as a thermal sink. High-heat components were placed in direct contact with the chassis, enabling efficient heat dissipation without active cooling elements. This setup minimized overheating risks, even in high-pressure, low-movement environments. To further optimize compactness and weight, Mistral utilized a blind-mate mechanism between boards, reducing the need for extensive cabling and minimizing internal clutter, which saved both weight and space.

Read full case study to know more!