Introduction

Mobile Command & Control Centre (MC&CC) platforms have started making their presence felt among Indian law-enforcement and homeland security agencies, primarily for VIP security and disaster management duties. However, as the platforms become more common and widely used, the same agencies would like to extend the operational scope of the MC&CC to other use-cases, some of which may involve a scenario where the MC&CC is caught in the middle of a firefight: tactical operations or use in areas where insurgents are active.

This brief looks at standards and options for armouring MC&CC platforms, so that their use can be extended to operations involving active engagement with insurgents or terrorists.

Armour Standards

There are several standards in circulation, defining protection against ballistics, with the more widely followed ones being those released by NATO, the United States, and the European Union. These standards specify protection strengths for glass, body armour, windows/doors/shutters and vehicles; and address different aspects of ballistics protection. Based on tests that measure the protection stregths of each of these pieces of equipment, a rating is given.

In the context of armoured MC&CC platforms in India, there is a need to address both protection from bullets as well as projectiles (artillery, IED blasts) and kinetic energy, as these armoured vehicles will most probably be used in insurgency-affected areas where the use of IEDs is prevalent.

The commonly referred to standards, for protection from bullets and projectiles are:

- STANAG 4569

NATO Standardization Agreement covering the standards for the “Protection Levels for Occupants of Logistic and Light Armored Vehicles”, under direct fire - STANAG 2920

NATO Standardization Agreement covering the standards for “Ballistic test method for personal armour materials and combat clothing”, from fragments of metal and shrapnel; also used to define protection levels for add-on armour, for armoured vehicles - MIL STD 662F

US Department of Defense standard similar to STANAG 2920 - EN 1063

Security glazing standard created by the European Committee for Standardization for measuring the protective strength of bullet-resistant glass - EN 1522

A standard created by the European Committee for Standardization for bullet-proof protection of doors, windows, shutters, transfer trays and all other bullet-proof materials: EN 1522 also requires that any glass incorporated into structures be tested in accordance with the corresponding EN 1063 - NIJ

NIJ Standards 0101.06 and 0108.01 are the standards for “Ballistic Resistance of Police Body Armor” and “Ballistic Resistant Protective Materials” respectively, developed by the National Institute of Justice (NIJ), US Department of Justice; similar to EN 1522

Protection Levels for Specific User-situations

Looking at three specific user-situations – personal arms attack, shrapnel protection, and projectile attack – the protection levels specified by the relevant standards are provided below.

Personal Arms Attack

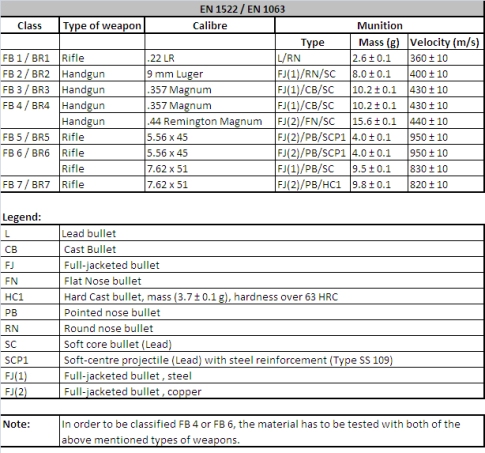

The NIJ Standard 0101.06/0108.01 and the Euro Standard EN 1522/EN 1063 define the protection levels for bullet-proof armour/materials as follows:

|

|

||||

|

|

Fragments and Shrapnel Protection

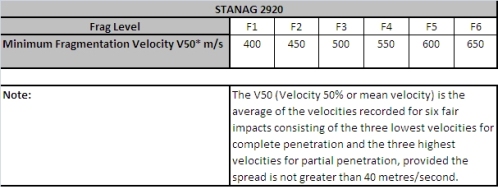

Fragments and shrapnel protection is covered under the STANAG 2920 standards. Tests are conducted by shooting FSPs (Fragment Simulating Projectiles) at the test material, while measuring the velocity of each FSP.

|

| Figure 3: STANAG 2920 |

Projectile Attack on Armoured Vehicle

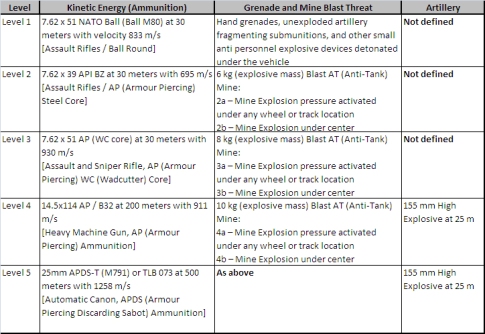

The STANAG 4569 standard defines protection for vehicles (light armoured) against firearms, mines, and artillery. There is no specific reference to IEDs, so it is usually up to the manufacturer to specify the level of protection against IEDs (size in kgs., constituent material, buried depth).

|

| Figure 4: STANAG 4569 |

Armoured Platforms in India

In India there are two routes available to users who wish to pick up armoured platforms.

Standard Design

A few of the automobile firms offer armoured platforms as part of their defence or homeland security offerings. Currently, Ashok Leyland, Mahindra Defence Systems , and Tata Motors sell vehicles that offer different levels of protection, primarily to the defence forces. In addition, Mahindra & Mahindra has a JV with BAE Systems in a company called Defence Land Systems India (DLSI), which recently handed over the first batch of Mine Protected Vehicle India (MPV-I) to the Jharkhand government; specifically to tackle the Maoist insurgency.

While the advantage of an off-the-shelf vehicle is the delivery time, these platforms are fixed configuration vehicles and offer very little scope for customisation. Off-the-shelf vehicles also offer the advantage of coming with the relevant armour-protection certifications.

Customised Design

For users who have specific functions required to be carried out from an armoured vehicle, an alternative is to build a custom body on a standard chassis. There are specialised fabricators, in India, who carry out the design and fabrication of armoured vehicles, based on user requirements and specifications. Customised armoured vehicles do not come with the relevant armour-protection certification. Certification is the end-user’s responsibility. Typically, once the hull of the vehicle is fabricated, the vehicle is sent across to a certification agency (e.g. Police Bureau of research and Development). After the necessary tests and certification, the rest of the fabrication work is completed.

Conclusion

Armoured platforms are still an exception, among law-enforcement agencies and homeland security authorities. Consequently, the user is quite confused about what specifications to lay down and the relative importance of each specification.

There are three questions the user needs to answer:

- What are the functions the vehicle is going to be to used for; from which the user arrives at the equipment and personnel load on the vehicle (both in terms and layout). This will allow the user to decide whether an off-the-shelf platform or a customised platform is the way forward.

- What is the level of protection required for the occupants of the vehicle: small-arms fire, IEDs, etc. Accordingly, the user will specify compliance to one of the standards, discussed in this brief, as a key specification. The user is well within its rights to specify customised armouring, but it should do so in the knowledge that such customisation comes at a high cost.

- What is the performance expected of the vehicle, once fully laden, functionally and armour-wise? The answer to this will allow the user to specify key performance features: power-to-weight ratio, ground clearance, gradeability, etc.

Mistral offers its MC&CC platforms in an armoured configuration and has a tie-up with an experienced fabricator of armoured vehicle bodies for meeting user requirements.